Sodium Alginate Beads Preparation

Always wear safety goggles. Sodium alginate is first dissolved in an aqueous system which can then be gelled when exposed to multivalent cations such as Ca 2 from CaCl 2.

Schematic Diagram Of The Preparation Of Beads By Ionotropic Gelation Method Scientific Diagram

Schematic Diagram Of The Preparation Of Beads By Ionotropic Gelation Method Scientific Diagram

Explore Sodium alginate beads preparation

Rinse the beaker graduated cylinder and petri dish.. Gel Beads and Worms. The invention discloses a preparation method of macroporous cross-linked sodium alginate gel beads. Add three or four drops of sodium alginate to the beaker.

Sodium alginate is a very large polymer with molecular weights in the range of 1 to 10 million the molecular weight of water is 18. OSA with the oxidation degree of 46 was used for the preparation of SAOSA gel beads. According to the method an aqueous solution of a mixture of sodium alginate and sodium sulfate is dropped into calcium chloride solution.

For matrix-type beads the fill material is typically incorporated into the aqueous system with the dissolved alginate prior to gelation. 3 Preparation of CaCl 2 solution 100 mM Estimated bench time. The FTIR spectra were obtained in the wave number range from 4000 to 450 cm -1.

In a blender add 2 g of sodium alginate for every 100 mL of deionized or distilled water. Sodium alginate solution 2 wv in deionized water was mixed with tetrandrine solution in HCl 01 N. 4 Alginate beads 22 Setup Protocol Dissolve 025 g alginate slowly in 10 ml 09 NaCl solution.

Sodium alginate gel beads are cleaned with ethanol and are subject. Avoid blending too long or you will get a foamy solution. Preparation of calcium alginate beads Ionic gelation method was utilized to prepare the calcium alginate beads.

The mixture was then dripped into 3 calcium chloride solution and stirred at 200 rpm using a. One type of polymer commonly used in the food industry is called Sodium Alginate. Measurements were performed on these samples with a Perkin Elmer 200 FT-IR spectrophotometer using potassium bromide pellets.

The prepared chitosansodium alginatecarboxymethyl cellulose beads was characterized by FTIR spectroscopy. The composite OSASA solution 3 wv with distinct OSA to SA percentage weight ratios were prepared 11 81 1241 ww. Synthesis of AlginateSLS Beads Aqueous sodium alginate and SLS mixed solution was prepared by dissolving the components in NaCl 1M solution at 60ºC under.

The specific surface area and aperture of the prepared SACMC gel beads were tested. While sodium alginate forms gel beads sodium sulfate forms calcium sulfate deposition. It is a naturally occurring polymer obtained from the giant kelp brown seaweed.

This forms a homogeneous structure throughout the bead. Floating beads were prepared from a sodium alginate solution containing CaCO3 or NaHCO3 as gas-forming agents. The effects of gas-forming agents on bead.

The aim of the research work was formulation and evaluation of sodium alginate beads containing voglibose for the effective use in the treatment of hyperglycemia. These consideration led to the objective of this study which was to prepare and evaluate oral sustained release product namely microbeads for ibuprofen by ionotropic gelation method using sodium alginate alone to overcome the fast disintegration of alginate beads in simulated intestine. PH-sensitive sodium alginatepolyvinyl alcohol hydrogel beads prepared by combined Ca 2 crosslinking and ze-thawing cycles for controlled release of diclofenac sodium.

Preparation of gel beads. The macro beads 285385 mm were prepared via different concentrations of alginate 05 10 15 and 20 gL dripping tip size 004014 cm and immersion into a predetermined concentration of calcium chloride CaCl. The gel beads containing oil were prepared by gentle mixing or homogenizing oil and water phase containing sodium alginate which was.

Alginatecarboxymethyl cellulose CMC gel beads were prepared in this study using sodium alginate SA and sodium CMC through blending and cross-linking. Use the scoop to transfer one or two of the alginate gel beads. Add it to the beaker.

During the entire dissolving process a mixing magnet must be used to keep mixing the solution. The mucoadhesive microbeads of sodium alginate-carbopol 934P were prepared by orifice-ionic gelation process with some modification which has been extensively used to prepare the large size alginate-carbopol beads. The solution was dropped to 1 CaCl2 solution containing 10 acetic acid for CO2 gas and gel formation.

2 Sodium Alginate Solution Mix the contents using a hand blender for about 15 minutes or until all of the sodium alginate has been dissolved. Autoclave the alginate solution at 121 C for 20 minutes sterilization. Measure 20 mL of calcium chloride solution with the graduated cylinder.

They were characterized by Fourier transform infrared spectroscopy scanning electron microscopy and. The beads were synthesized using sodium alginate in the presence of sodium dodecyl sulfate as foaming agent NaCl as porogen agent and CaCl 2 as cross-linker. Rinse the beaker graduated cylinder and petri dish.

Fabrication Of Detonation Nanodiamond Sodium Alginate Hydrogel Beads And Their Performance In Sunlight Triggered Water Release Rsc Advances Rsc Publishing Doi 10 1039 C9ra03914g

Fabrication Of Detonation Nanodiamond Sodium Alginate Hydrogel Beads And Their Performance In Sunlight Triggered Water Release Rsc Advances Rsc Publishing Doi 10 1039 C9ra03914g

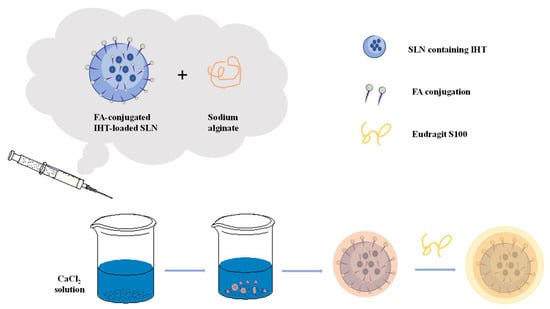

Figure 1 From Chitosan Reinforced Alginate Controlled Release Beads Of Losartan Potassium Design Formulation And In Vitro Evaluation Semantic Scholar

Figure 1 From Chitosan Reinforced Alginate Controlled Release Beads Of Losartan Potassium Design Formulation And In Vitro Evaluation Semantic Scholar

One Step Dry Synthesis Of An Iron Based Nano Biocomposite For Controlled Release Of Drugs Rsc Advances Rsc Publishing Doi 10 1039 D0ra01133a

One Step Dry Synthesis Of An Iron Based Nano Biocomposite For Controlled Release Of Drugs Rsc Advances Rsc Publishing Doi 10 1039 D0ra01133a

Schematic Of The Synthesis Procedure A Preparation Of Nr Alginate Scientific Diagram

Schematic Of The Synthesis Procedure A Preparation Of Nr Alginate Scientific Diagram

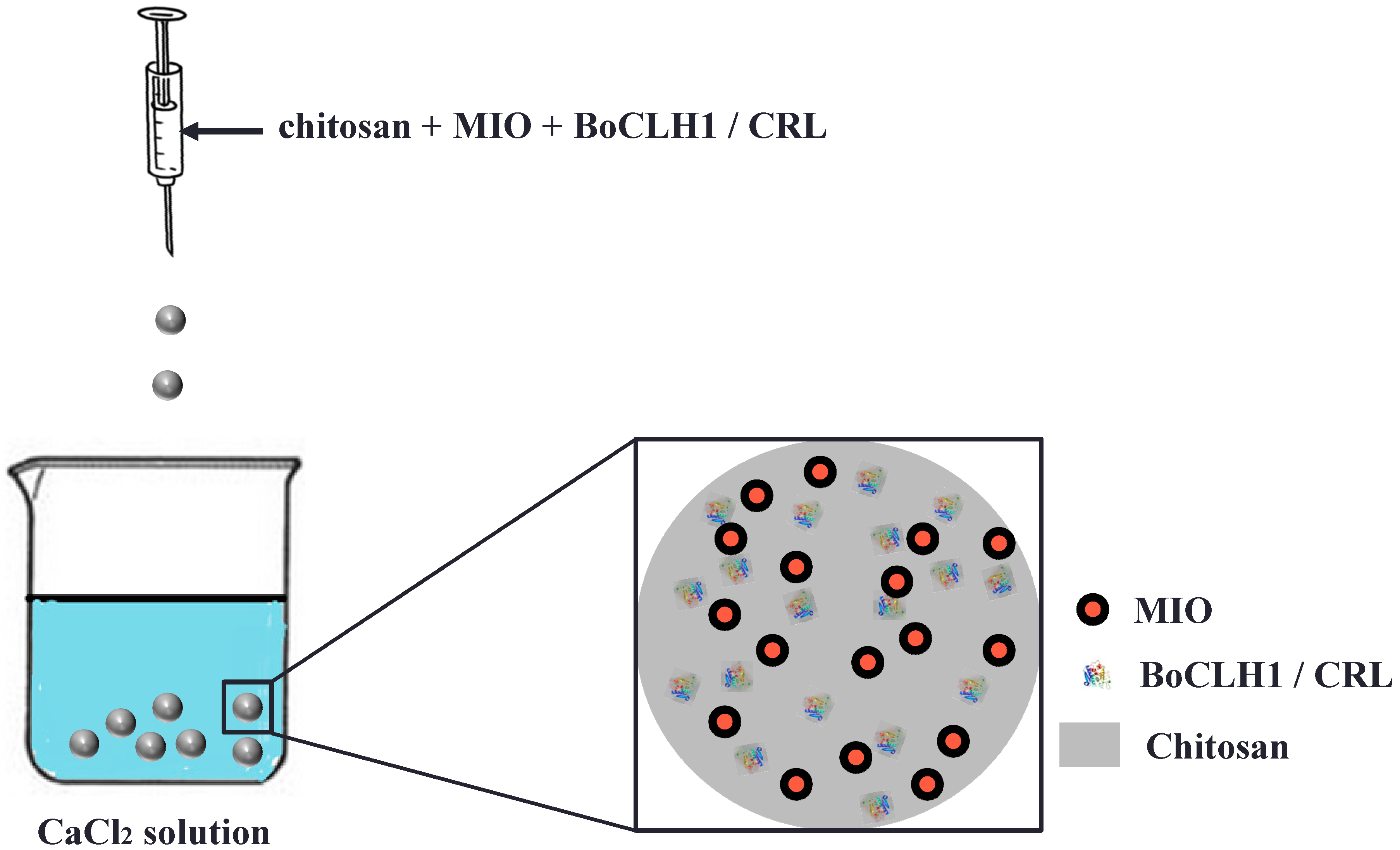

Molecules Full Text Immobilization Of Brassica Oleracea Chlorophyllase 1 Boclh1 And Candida Rugosa Lipase Crl In Magnetic Alginate Beads An Enzymatic Evaluation In The Corresponding Proteins

Molecules Full Text Immobilization Of Brassica Oleracea Chlorophyllase 1 Boclh1 And Candida Rugosa Lipase Crl In Magnetic Alginate Beads An Enzymatic Evaluation In The Corresponding Proteins

Scheme Of The Preparation Of Sodium Alginate Gelatin Core Shell Beads Scientific Diagram

Scheme Of The Preparation Of Sodium Alginate Gelatin Core Shell Beads Scientific Diagram

Alginate Beads Preparation By Diffusion Setting Method Scientific Diagram

Alginate Beads Preparation By Diffusion Setting Method Scientific Diagram

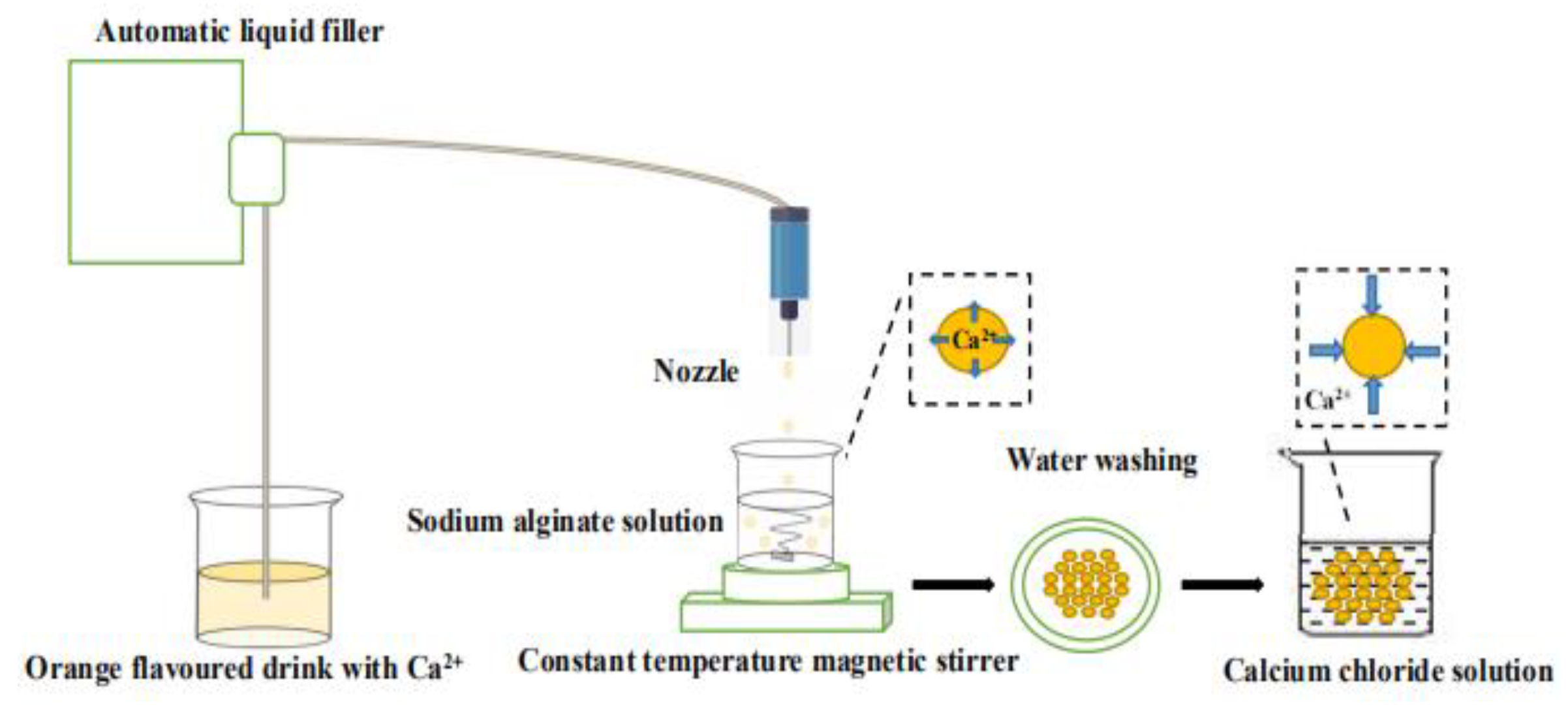

Applied Sciences Full Text Preparation Of The Orange Flavoured Boba Ball In Milk Tea And Its Shelf Life

Applied Sciences Full Text Preparation Of The Orange Flavoured Boba Ball In Milk Tea And Its Shelf Life

A A Two Step Process For Preparation And Immobilization Of Xca Scientific Diagram

A A Two Step Process For Preparation And Immobilization Of Xca Scientific Diagram

Marine Drugs Full Text Preparation Of Alginate Based Biomaterials And Their Applications In Biomedicine

Marine Drugs Full Text Preparation Of Alginate Based Biomaterials And Their Applications In Biomedicine

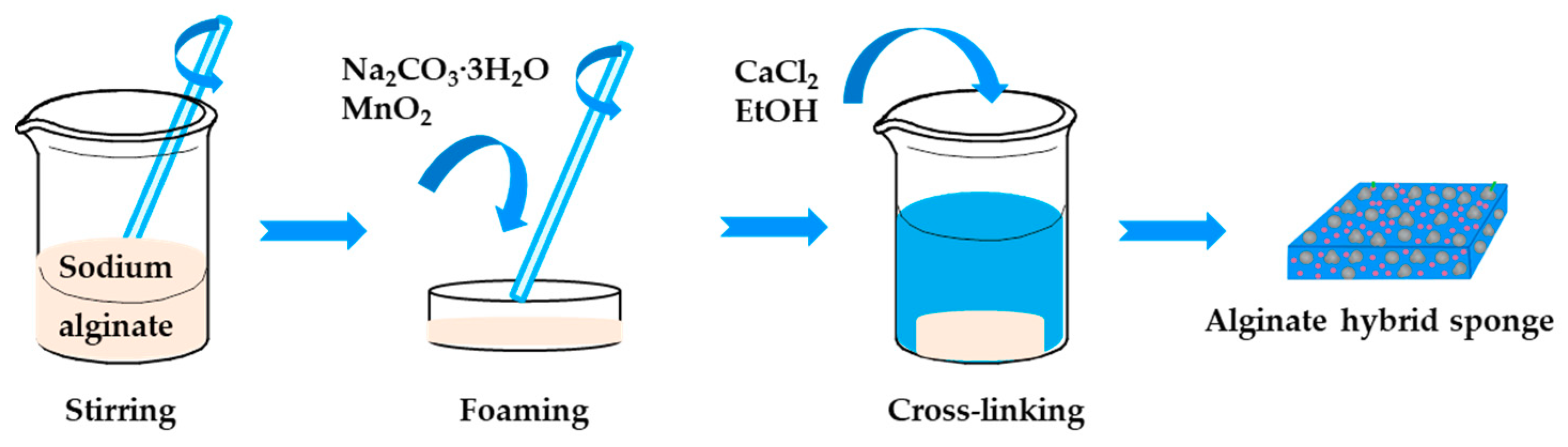

Polymers Full Text An Alginate Hybrid Sponge With High Thermal Stability Its Flame Retardant Properties And Mechanism

Polymers Full Text An Alginate Hybrid Sponge With High Thermal Stability Its Flame Retardant Properties And Mechanism

Schematic Representation Of Alginate Inulin Beads Preparation With Scientific Diagram

Schematic Representation Of Alginate Inulin Beads Preparation With Scientific Diagram

The Ionotropic Congealing Method Of Sodium Alginate Used To Prepare Scientific Diagram

The Ionotropic Congealing Method Of Sodium Alginate Used To Prepare Scientific Diagram

Zinc Oxide Templating Of Porous Alginate Beads For The Recovery Of Gold Ions Sciencedirect

Zinc Oxide Templating Of Porous Alginate Beads For The Recovery Of Gold Ions Sciencedirect

Schematic View Of The Process Employed To Produce Alumina Sodium Scientific Diagram

Schematic View Of The Process Employed To Produce Alumina Sodium Scientific Diagram

Multilayer Calcium Alginate Beads Containing Diatom Biosilica And Bacillus Subtilis As Microecologics For Sewage Treatment Sciencedirect

Multilayer Calcium Alginate Beads Containing Diatom Biosilica And Bacillus Subtilis As Microecologics For Sewage Treatment Sciencedirect

Optimization Of Gallic Acid Encapsulation In Calcium Alginate Microbeads Using Box Behnken Experimental Design Springerlink

Optimization Of Gallic Acid Encapsulation In Calcium Alginate Microbeads Using Box Behnken Experimental Design Springerlink

A Physico Chemical Approach To Production Of Alginate Beads By Emulsification Internal Ionotropic Gelation Sciencedirect

A Physico Chemical Approach To Production Of Alginate Beads By Emulsification Internal Ionotropic Gelation Sciencedirect

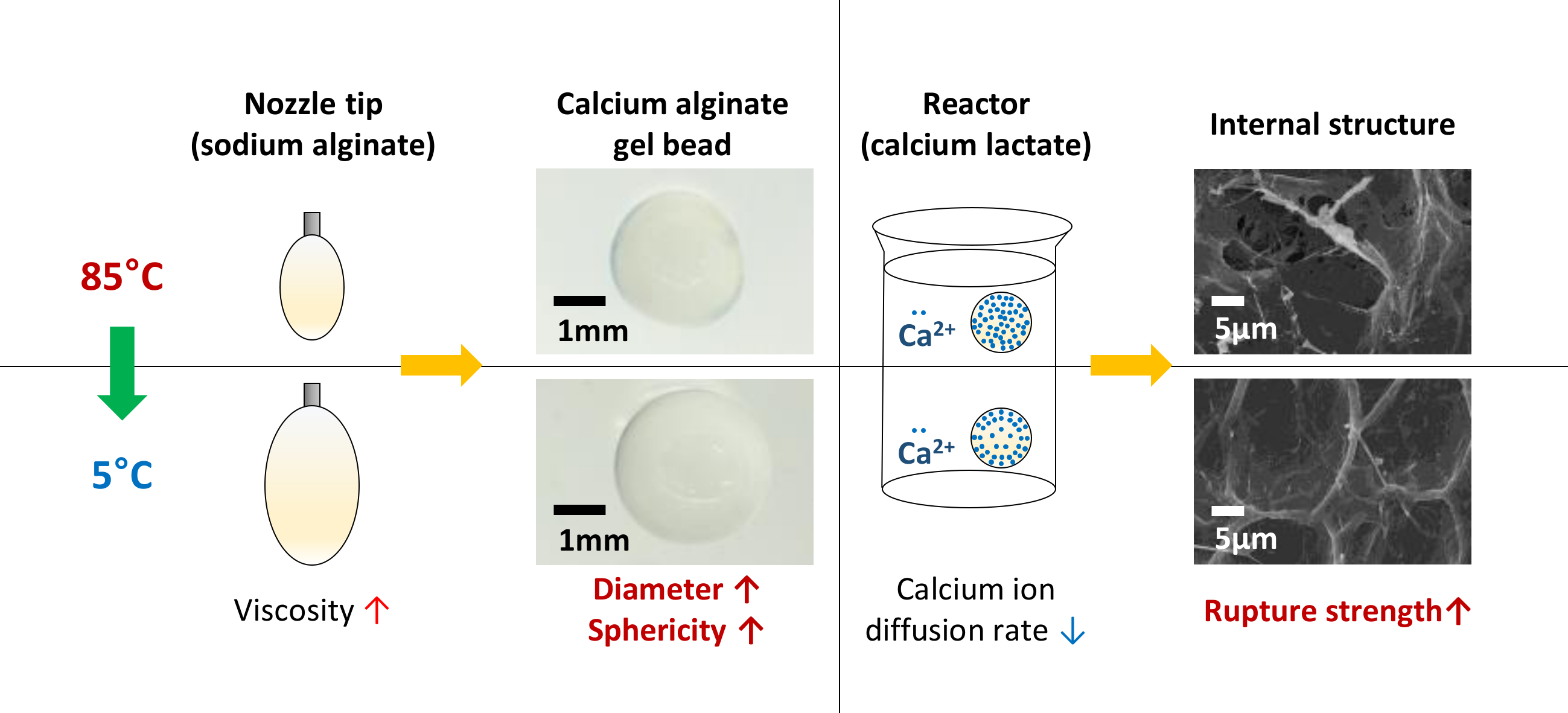

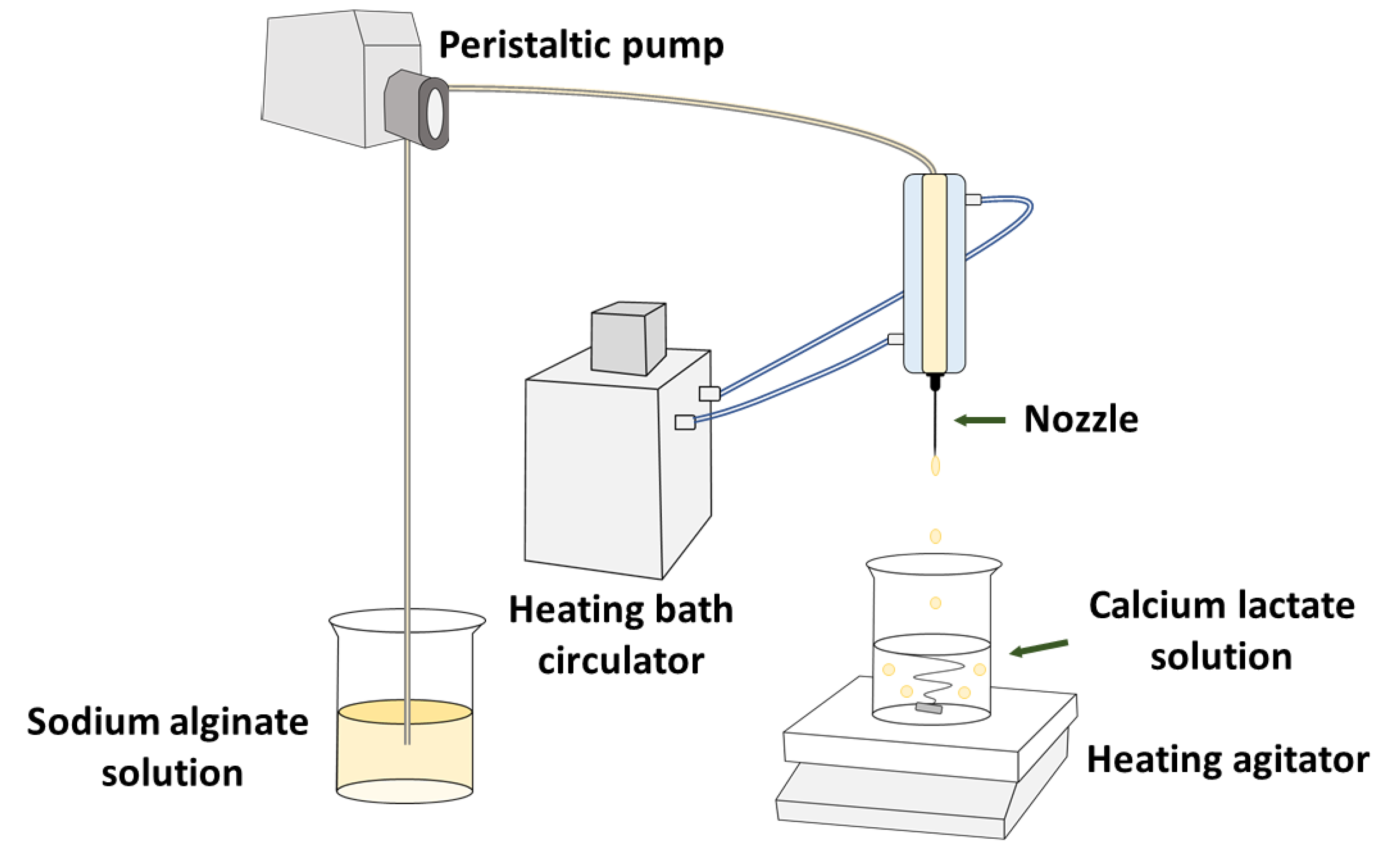

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Urea Formaldehyde Modified Alginate Beads With Improved Stability And Enhanced Removal Of Pb2 Cd2 And Cu2 Sciencedirect

Urea Formaldehyde Modified Alginate Beads With Improved Stability And Enhanced Removal Of Pb2 Cd2 And Cu2 Sciencedirect

Schematic Diagram Represents The Formation Of Alginate Beads Using Scientific Diagram

Schematic Diagram Represents The Formation Of Alginate Beads Using Scientific Diagram

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Microfluidic Preparation Shrinkage And Surface Modification Of Monodispersed Alginate Microbeads For 3d Cell Culture Rsc Advances Rsc Publishing Doi 10 1039 C9ra01443h

Microfluidic Preparation Shrinkage And Surface Modification Of Monodispersed Alginate Microbeads For 3d Cell Culture Rsc Advances Rsc Publishing Doi 10 1039 C9ra01443h