Sodium Alginate Beads Calcium Chloride

Calcium alginate beads formula. Thus in an attempt to enhance synthetic seeds production the current study was conducted to assess the effects of sodium alginate as encapsulating agent and calcium chloride as complexing.

Development And Evaluation Of A Calcium Alginate Based Oral Ceftriaxone Sodium Formulation Abstract Europe Pmc

Development And Evaluation Of A Calcium Alginate Based Oral Ceftriaxone Sodium Formulation Abstract Europe Pmc

Unique idea Sodium alginate beads calcium chloride

In this experiment calcium causes alginate to cross-link and trap water.. Some calcium salts eg CaCl 2 calcium lactate were readily soluble and fully dissociated in water and. Irrespective of the sodium alginate and calcium chloride concentration external gelation beads had an encapsulation efficiency around 78 and internal gelation beads had an encapsulation efficiency around 23. Were prepared by gentle mixing or homogenizing oil and water phase containing sodium alginate which was then extruded into calcium chloride solution to produce gel beads.

The other product of the reaction is sodium chloride or common table salt. All formulae for calcium alginate beads preparation can be seen in Table 1. 770-774 the present research is dedicated to the formation of alginate beads from sodium alginate calcium salts and sucrose.

Calcium alginate beads are made of sodium alginate and calcium chloride. Adjusted and the alginate beads were extruded into a 5 CaCl 2 bath before being drained and dried. Here we report on the microfluidic assisted fabrication of calcium alginate Ca-alginate beads by on-chip picoinjection of aqueous calcium chloride CaCl2 in emulsified aqueous sodium alginate Na-alginate droplets or by picoinjection of Na-alginate solution in emulsified aqueous CaCl2 droplets.

Could be encapsulated and released through alginate beads. The optimum condition. Beads form because the sodium alginate drops are round and begin to crosslink once they hit the calcium chloride solution.

A calcium ion can attach to two different polymer strands cross-linking them. Because of SAs ability to form a stable and bioadhesive gel with calcium ions 13 some sensitive drugs 14 15 protein 16 living cells 17 etc. The beads were dried by lyophilization to be analyzed their surface.

A gel shell forms around the bead and thickens when the bead is. Calcium alginate forms very quickly when sodium alginate reacts with calcium chloride. Jell-O gets its structure from gelatin which is a naturally occuring protein.

So-dium alginate solutions in 30 gkg-1 and 60 gkg concentrations with calcium chloride dihydrate in 40 gkg and 70 gkg-1. Ammonium hydrogen fluoride NH 4 HF 2 AR Sodium alginate SA AR Sodium hydroxide NaOH AR Calcium chloride CaCl 2 AR Methylene blue MB BS and Absolute ethanol CH 3 CH 2 OH AR were all purchased from Kelong Chemical Reagent Factory Chengdu China. The beads with best characteristics were selected on the basis of physical and sensory evaluation.

The effect of sodium alginate concentration and chitosan concentration on the particle size and loading efficacy was studied. The size and surface characteristics of the beads were significantly affected depending upon the sodium alginate and calcium chloride concentration. The effects of types of oil and its proportions on the morphology and release characteristics were optimized.

The system was magnetically stirred at 60 rpm. Hydrochloric acid HCl AR 3638 was obtained from Sinopharm Chemical Reagent Co. The chemical reaction between sodium alginate and calcium ions is dependent upon the solubility and availability of calcium ions.

Bovine serum albumin-loaded beads were prepared by ionotropic gelation of alginate with calcium chloride and chitosan. When a sodium alginate solution is mixed with a calcium chloride solution the calcium ions replace the sodium ions that are attached to the alginate polymer. The objective of this work is to study the chemical reaction between sodium alginate drop and calcium chloride film and instantaneous formation of calcium alginate gel.

The complexity of this work is the simultaneous effect of both liquid and solid surface on drop impact gelation process. The obtained beads in chloride solution could stand for 15 min after the reaction has completed. Based on the results the 2 wv sodium alginate and 3 wv calcium chloride concentration was used to prepare sugar loaded alginate beads.

NaAlginate CaCl 2 2 NaCl CaAlginate 2 _ _ _ 2. It is important to emphasize that the bead itself is merely the slow release mechanism and that depending on what is added the bead. The diameter of the beads formed is dependent on the size of the needle used.

Usually calcium alginate beads are formed by dropping soluble SA solution with certain concentration into an aqueous solution of Ca 2 ions made from calcium chloride CaCl 2. A 2 wt solution of sodium alginate contains 2 grams of sodium alginate in 100 mL of water. Effect of sodium alginate and calcium chloride treatments on nature colour and quality of encapsulation and survival rate of manufactured seeds.

The mixture was then dripped into 3 calcium chloride solution and stirred at 200 rpm using a magnetic stirrer. 14-α-D-glucose glucanohydrolase of MP Biomedicals type corn starch BDH and HCl BDH were used in this study. The calcium alginateSLS beads without using NaCl were obtained by dropping through a needle of a syringe the mixed sodium alginateSLS solution into a 1 wt calcium chloride solution.

Sodium alginate salt type Spectrum Chemical Mfg. Corp calcium chloride CaCl 2 2H 2 O of BDH type fungal amylase powder EC 3211. The instant formation of a bead when sodium alginate is added to calcium chloride makes the process time equipment and energy efficient.

A variety of oils were used. This cross-linking of the alginate polymers via calcium ions forms a network of polymer chains that trap water thus creating the beads and worms. In this experiment calcium causes alginate to cross-link and trap water.

Reversible Crosslinking Of Alginate By Dications During The Scientific Diagram

Reversible Crosslinking Of Alginate By Dications During The Scientific Diagram

Calcium Alginate Beads Formed From 20 30 Cm These Beads Were Obtained Scientific Diagram

Calcium Alginate Beads Formed From 20 30 Cm These Beads Were Obtained Scientific Diagram

crhhrutjg2frr7pcaf7eokxycxksb8qqwztt6jjfaoky Pvlpm

Two Kinds Of Ketoprofen Enteric Gel Beads Ca And Cs Sa Using Biopolymer Alginate Sciencedirect

Two Kinds Of Ketoprofen Enteric Gel Beads Ca And Cs Sa Using Biopolymer Alginate Sciencedirect

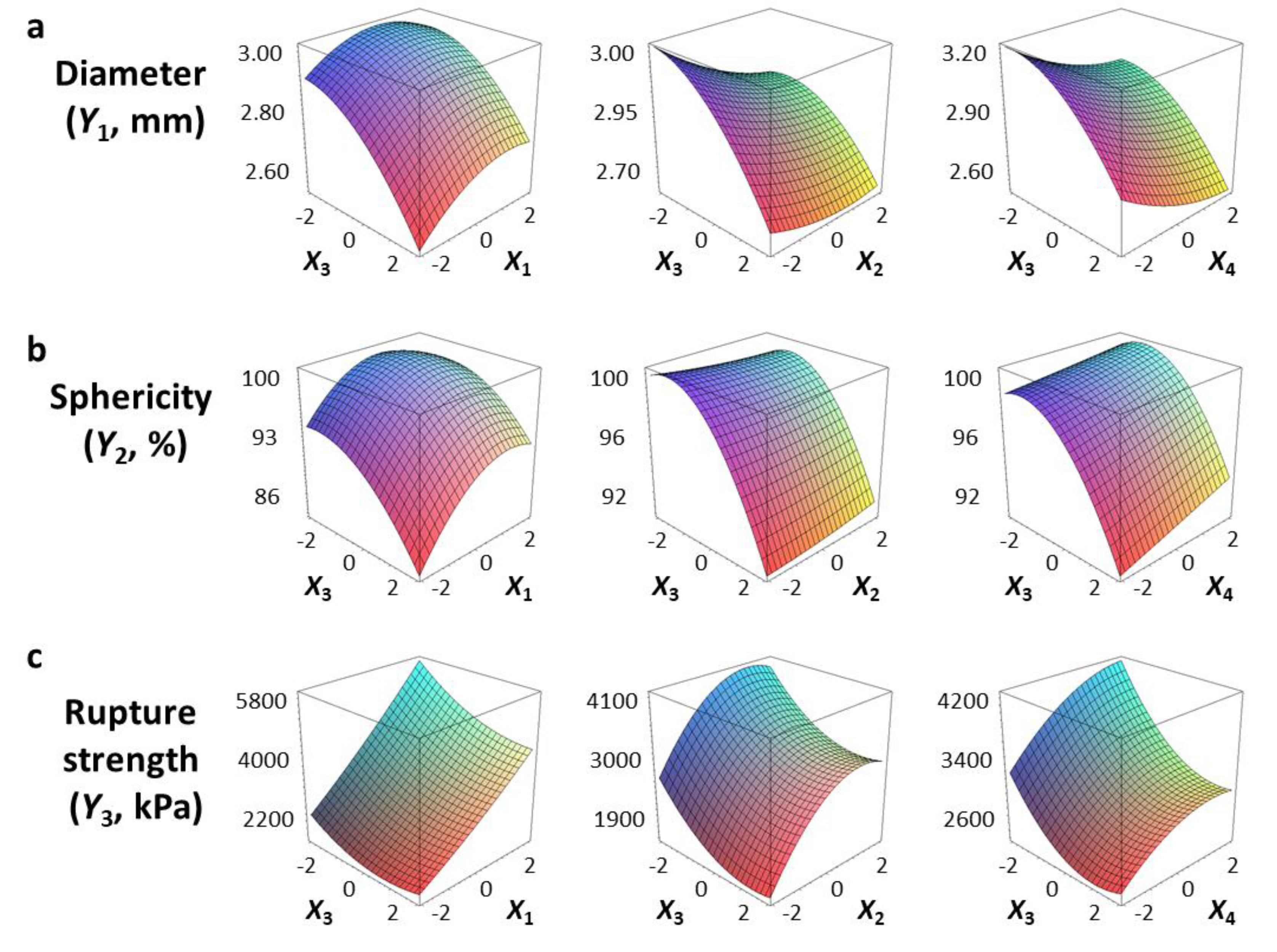

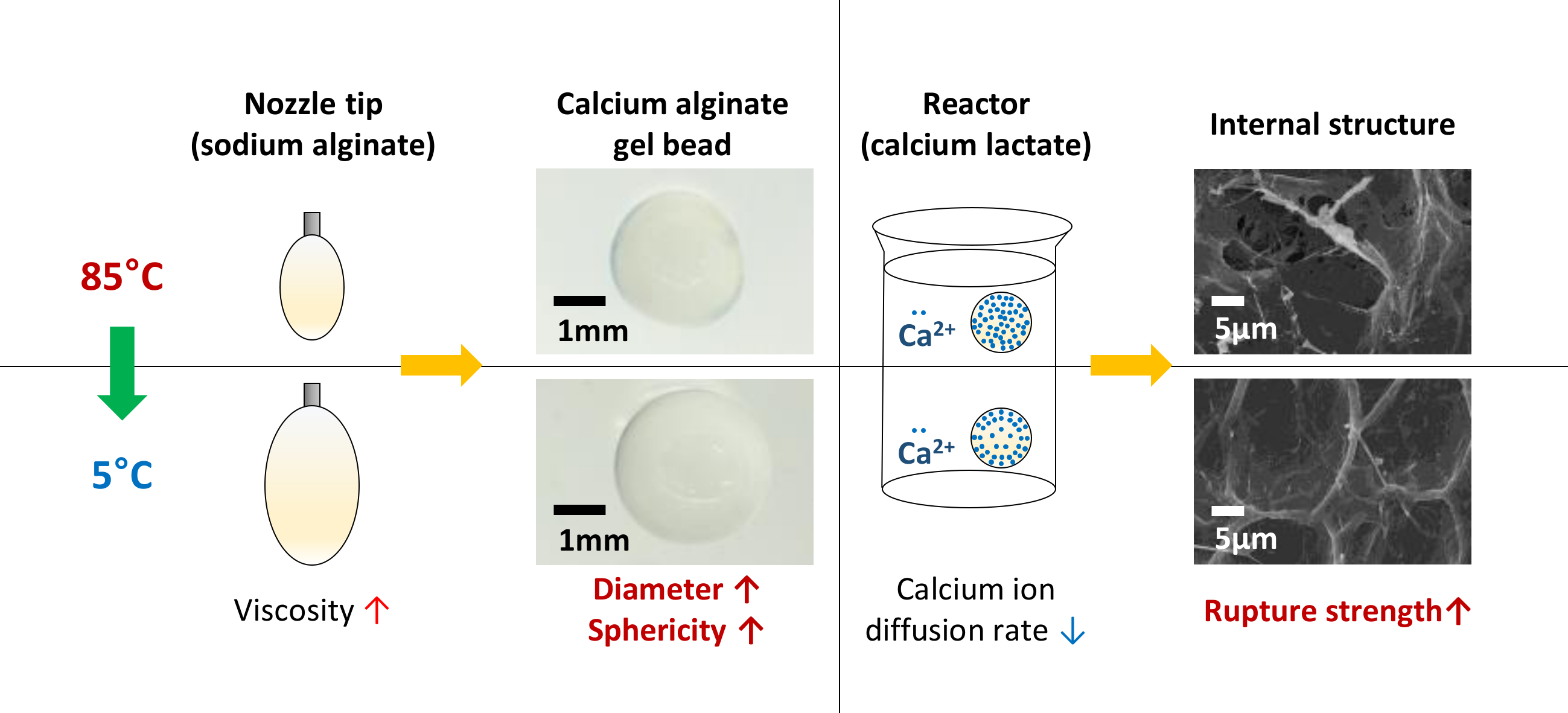

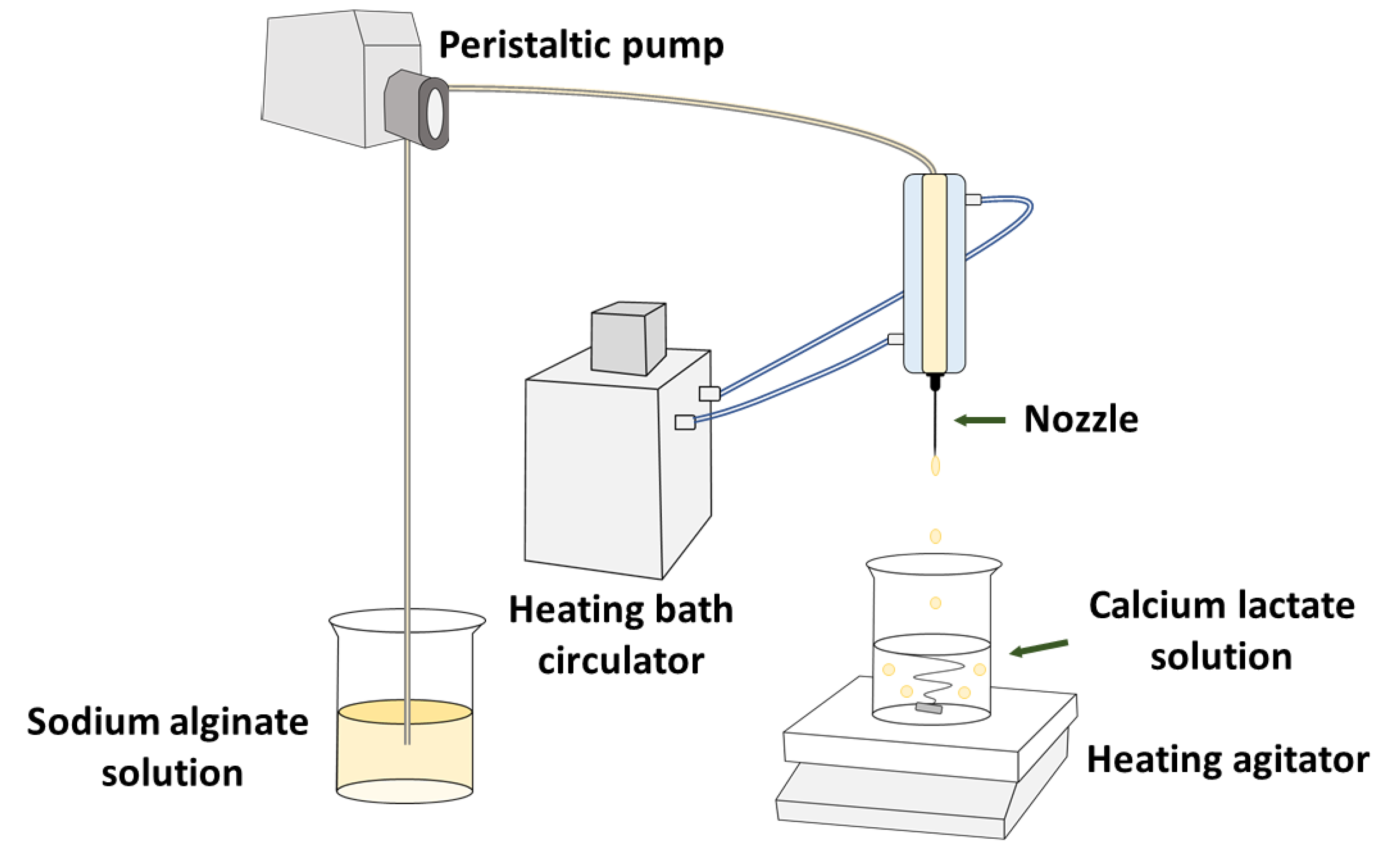

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Calcium Alginate Beads As Carriers For Biocatalyst Encapsulation

Calcium Alginate Beads As Carriers For Biocatalyst Encapsulation

Showing The Atr Ftir Spectra Of A Bso B Sodium Alginate C Scientific Diagram

Showing The Atr Ftir Spectra Of A Bso B Sodium Alginate C Scientific Diagram

Characterization Of Spirulina Alginate Beads Formed Using Ionic Gelation Abstract Europe Pmc

Characterization Of Spirulina Alginate Beads Formed Using Ionic Gelation Abstract Europe Pmc

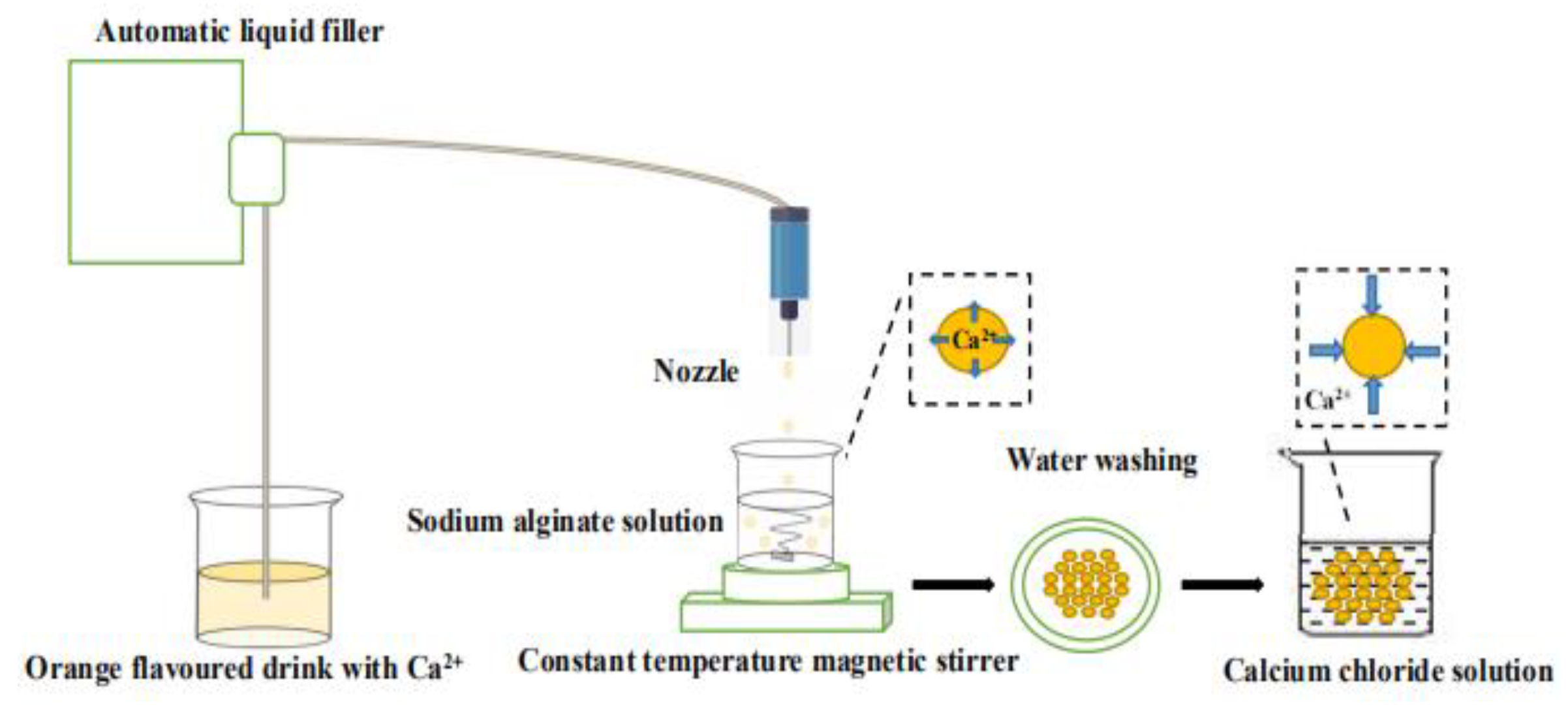

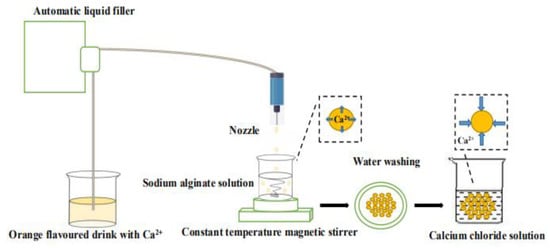

Applied Sciences Full Text Preparation Of The Orange Flavoured Boba Ball In Milk Tea And Its Shelf Life

Applied Sciences Full Text Preparation Of The Orange Flavoured Boba Ball In Milk Tea And Its Shelf Life

Hydrogels For Potential Food Application Effect Of Sodium Alginate And Calcium Chloride On Physical And Morphological Properties Semantic Scholar

Hydrogels For Potential Food Application Effect Of Sodium Alginate And Calcium Chloride On Physical And Morphological Properties Semantic Scholar

Applied Sciences Full Text Preparation Of The Orange Flavoured Boba Ball In Milk Tea And Its Shelf Life

Applied Sciences Full Text Preparation Of The Orange Flavoured Boba Ball In Milk Tea And Its Shelf Life

Polymers Full Text Characteristics Compression And Buffering Performance Of Pomelo Like Hierarchical Capsules Containing Shear Thickening Fluid

Polymers Full Text Characteristics Compression And Buffering Performance Of Pomelo Like Hierarchical Capsules Containing Shear Thickening Fluid

Urea Formaldehyde Modified Alginate Beads With Improved Stability And Enhanced Removal Of Pb2 Cd2 And Cu2 Sciencedirect

Urea Formaldehyde Modified Alginate Beads With Improved Stability And Enhanced Removal Of Pb2 Cd2 And Cu2 Sciencedirect

Schematic Diagram Depicting The Production Of Calcium Alginate Hydrogel Scientific Diagram

Schematic Diagram Depicting The Production Of Calcium Alginate Hydrogel Scientific Diagram

Gummy Capsules Sodium Alginate A Polymer And Blue

Effects Of Alginate Concentration Immobilization Conditions Mnp Scientific Diagram

Effects Of Alginate Concentration Immobilization Conditions Mnp Scientific Diagram

Microencapsulation Of Sulfur By Calcium Alginate Anozie 2021 Journal Of Applied Polymer Science Wiley Library

Microencapsulation Of Sulfur By Calcium Alginate Anozie 2021 Journal Of Applied Polymer Science Wiley Library

Preparation Of Porous Calcium Alginate Beads And Their Use For Adsorption Of O Nitrophenol From Aqueous Solutions Semantic Scholar

Preparation Of Porous Calcium Alginate Beads And Their Use For Adsorption Of O Nitrophenol From Aqueous Solutions Semantic Scholar

Redox Reactions In Sodium Alginate Beads

Dsc Thermogram A Sodium Alginate B Calcium Chloride C Scientific Diagram

Dsc Thermogram A Sodium Alginate B Calcium Chloride C Scientific Diagram

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Foods Full Text Changes In The Physical Properties Of Calcium Alginate Gel Beads Under A Wide Range Of Gelation Temperature Conditions

Tga Thermograms Of Alginate Bead A And Cs Encapsulated With Scientific Diagram

Tga Thermograms Of Alginate Bead A And Cs Encapsulated With Scientific Diagram

Figure 1 From Chitosan Reinforced Alginate Controlled Release Beads Of Losartan Potassium Design Formulation And In Vitro Evaluation Semantic Scholar

Figure 1 From Chitosan Reinforced Alginate Controlled Release Beads Of Losartan Potassium Design Formulation And In Vitro Evaluation Semantic Scholar