Weld Bead Geometry And Shape Relationship

The important parameters in arc welding are arc voltage welding current welding speed and they affect the weld bead shape the stability of the welding process and weld quality. Modeling of Weld Bead Geometry and Shape Relationships in Submerged Arc Welding using Developed Fluxes.

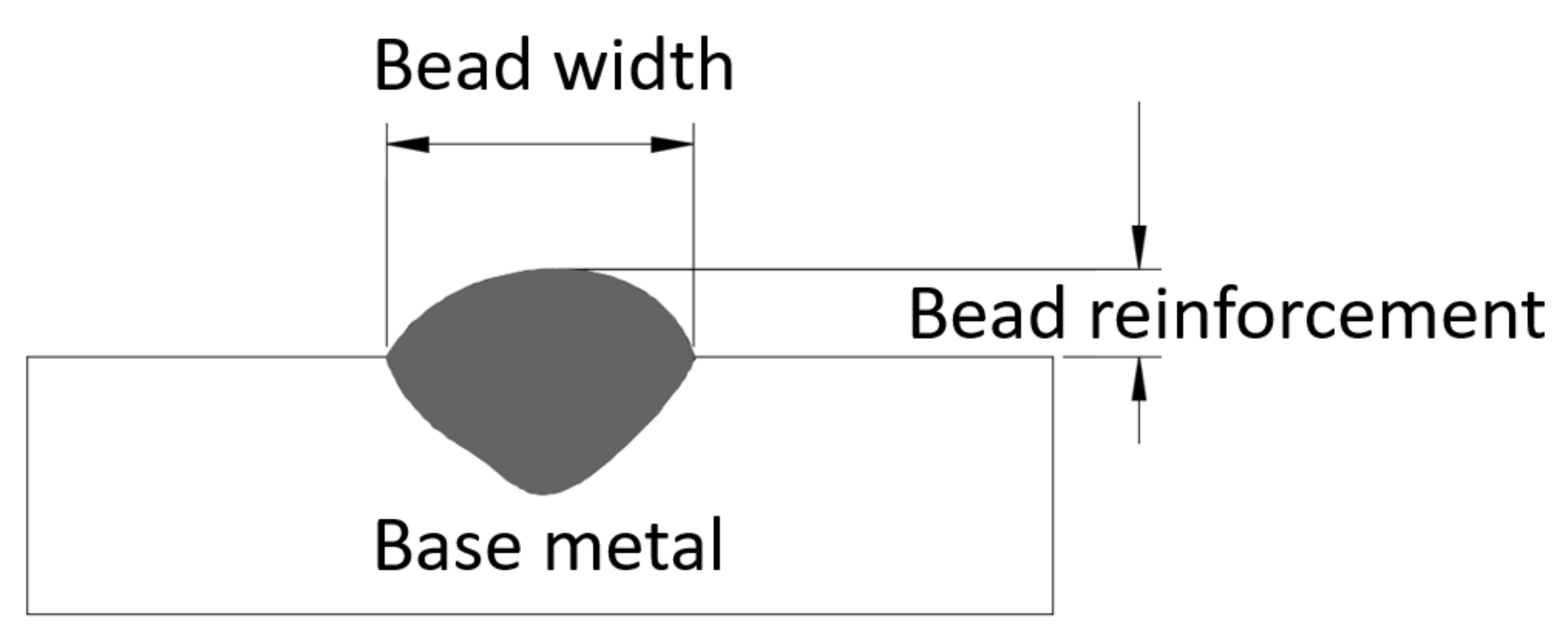

Schematic Illustration Of A Bead On Plate And The Section Line Of The Scientific Diagram

Schematic Illustration Of A Bead On Plate And The Section Line Of The Scientific Diagram

There are different Weld bead geometry and shape relationship

They can be used in two ways.. The weld bead width is known to be a highly significant factor affecting the geometrical aspects of the weldment. To automate a welding process which is the present trend in fabrication industry it is essential that mathematical models have to be developed to relate the process variables to the weld bead parameters. To predict the three most important dimensions of the weld bead geometry and shape relationship a mathematical model have been developed using five level factorial techniques for SAW of pipes.

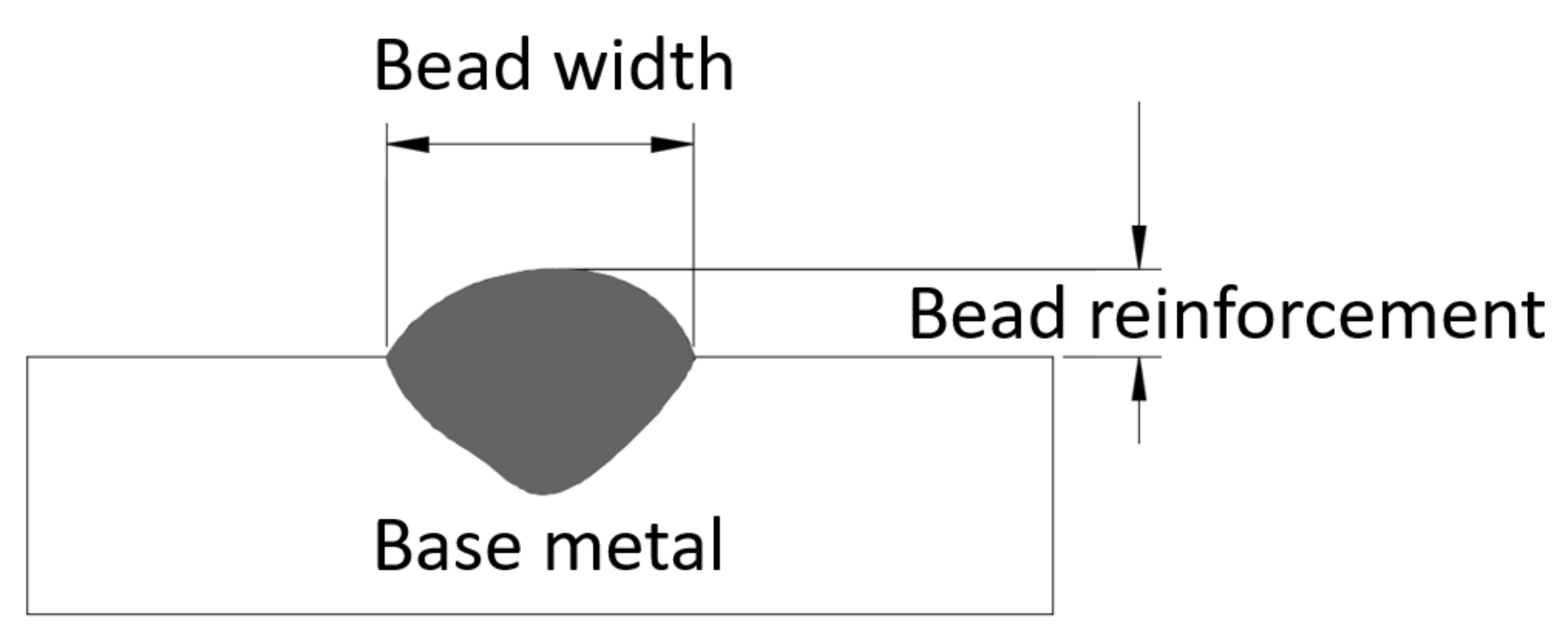

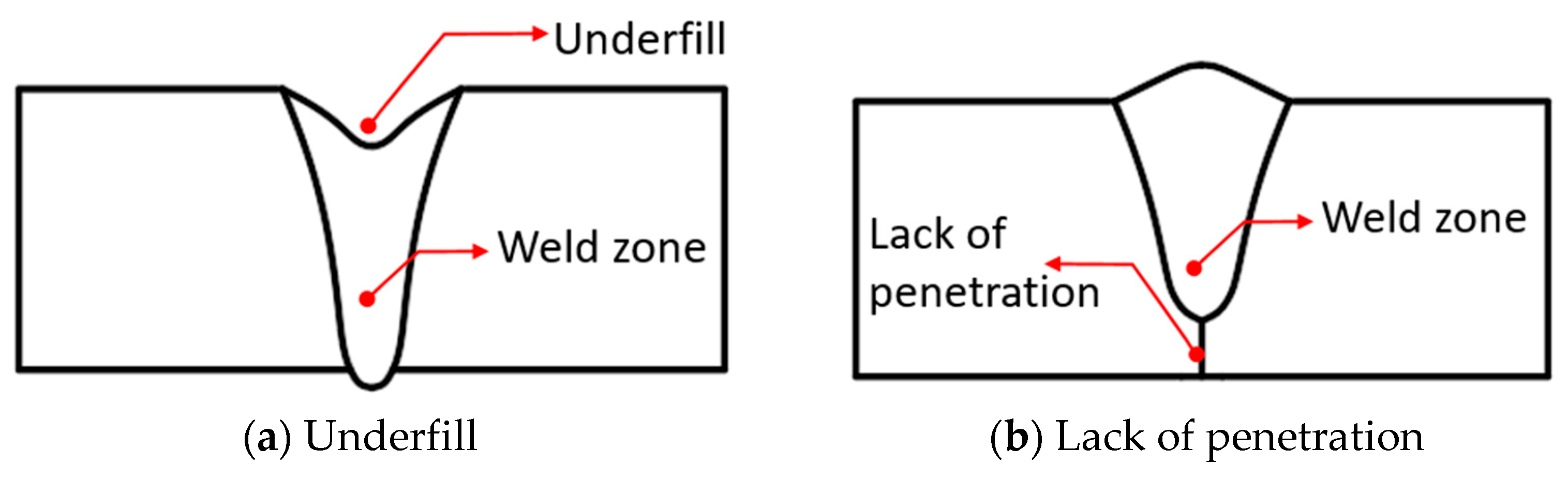

To identify the combination of input that jointly optimizes the responses such as penetration reinforcement and bead width dilution. Inaccurate weld bead shape leads to the failure of the weldment. Therefore it is necessary to study the relationship between in process parameters and bead parameters to study clad bead geometry.

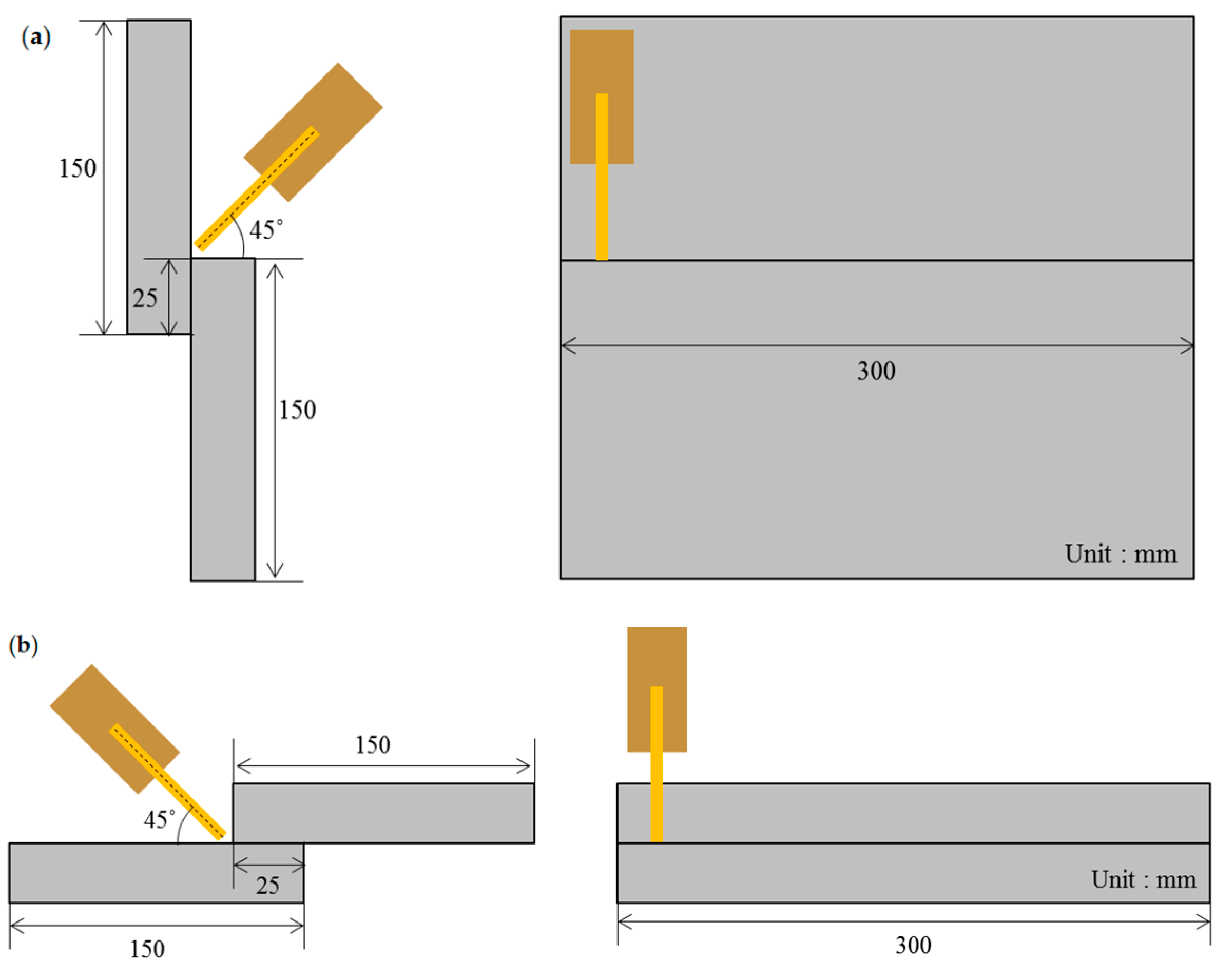

Load-carrying capacity of weld joints could be identified by its shape and size where weld bead geometry and shape relationship parameters are of utmost importance. Weld bead geometry and shape relationships in submerged arc welding of pipes. Is difficult to confirm because the stress concentration effect on the weld bead is dominant in the lap-fillet-joint-shaped arc weld 4.

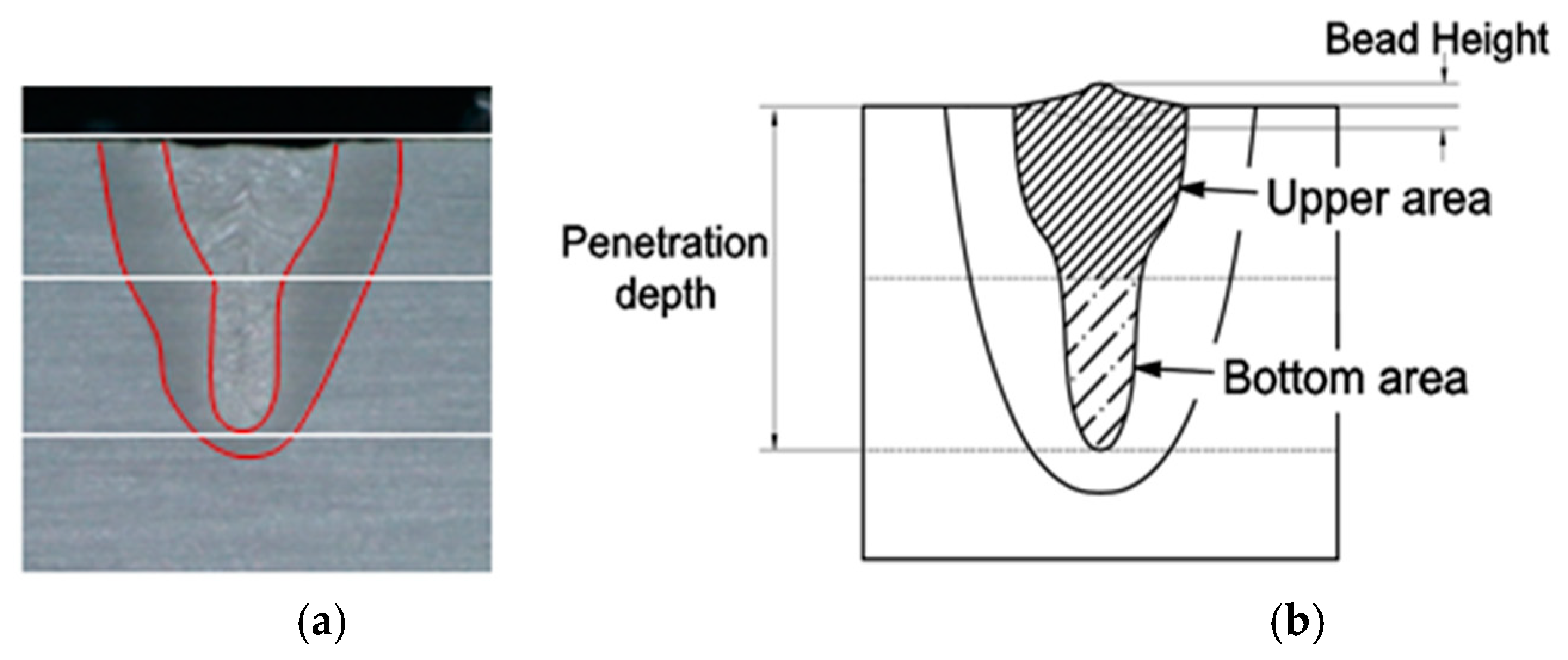

The models developed have been checked for their adequacy and significance by using the F-test and the t-test respectively. 32 Weld bead geometry Fig. Dilution widthpenetration and widthreinforcement as.

Downhand or flat welding position gives the most satisfactory bead shape and all modes of metal transfer can be effectively utilised. Weld quality mainly depends on the weld bead geometry and mechanical-metallurgical characteristics of the welded joint which has a direct relationship with the type of welding process being used and its input process parameters ie. The mathematical models furn ished above provide one to one relationships between process parameters and weld bead geometry.

Pred icting weld bead geometry based on in p u t p aramet ers an d Pred ict in g p ro cess parameters for a desired weld bead specification. Welding current arc voltage travel speed etc. Mathematical models have been developed for SAW of pipes using five level factorial techniques to predict three critical dimensions of the weld bead geometry and shape relationships.

As for cladding is concerned the desirable weld bead geometry is one which has maximum depth of penetration minimum bead width minimum reinforcement and minimum percentage of dilutionThis can be achieved by adopting multi objective optimization procedure. Emodels were checked for their adequacy and signi cance by using. Composition of metal but also by clad bead shape.

For the purpose of prediction as well as better control of weld bead geometry welding process is mathematically modeled for each weld bead shape-related parameter in relation to process variables. The quality of the weldment depends on meeting the requirements like appropriate weld bead geometry affected by different welding process parameters. Heat input and preheating temperature together can control the cooling time of weld which in turn determines the weld microstructure and its mechanical properties.

They investigated bead penetration weld width reinforcement. Ey have developed mathematical models for submerged arc welding of pipes using ve-level factorial techniques to predict three critical dimensions of theweldbeadgeometryandshaperelationships. Therefore it is difficult to determine the unique relationship between the weld bead geometry and the combination of various welding conditions.

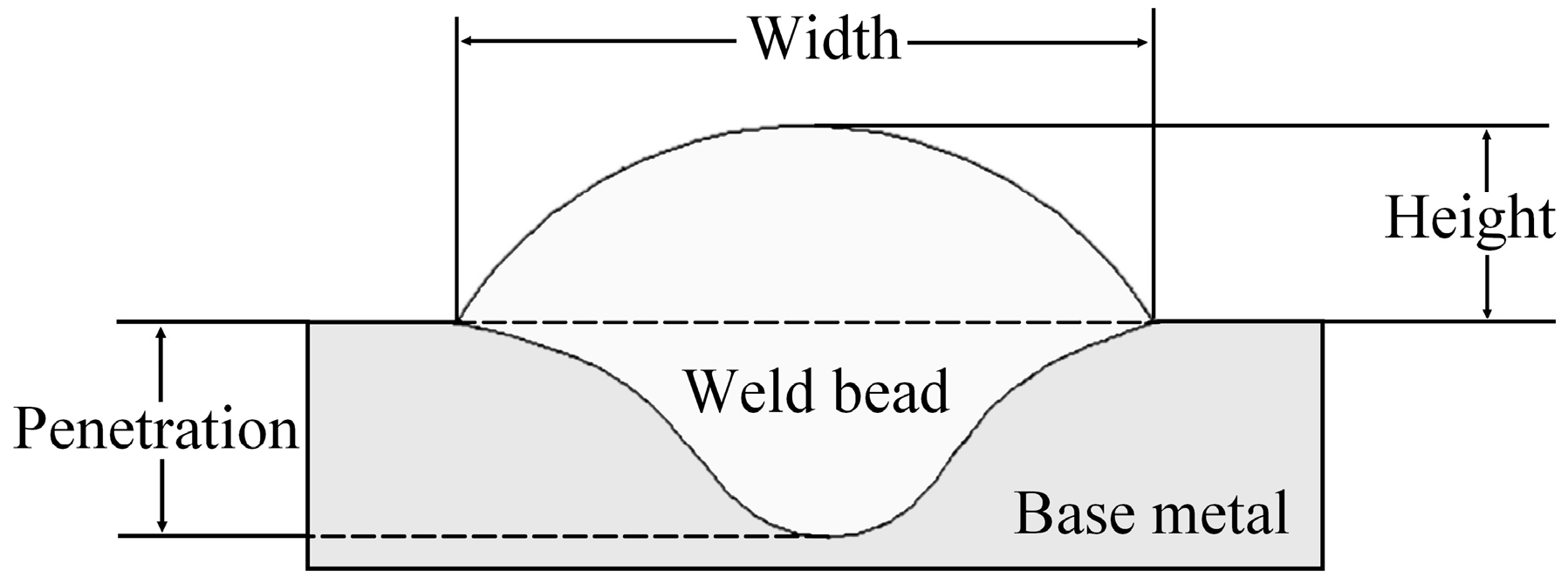

Shape sizes of the weld bead geometries including the weld width the penetration and the weld reinforcement are listed in Table 1. The thickness ranged between 10 and 16 mm. 5 shows the weld bead geometries of GMAW with different polarities at ambient pressures of 01 MPa 04 MPa 07 MPa and 10 MPa.

Therefore a number of previous studies have been carried out to clarify the relationship between weld bead shape and fatigue strength in lap fillet joint arc welding. It has been established experimentally that as a first approximation the welding speed S for a well shaped weld should be based on the following relationship. Weld bead geometry is also affected by the position in which the work- piece is held with respect to the welding gun.

In addition to main and interaction effects relationship of each weld bead shape-relationship parameter with heat input as well as weld cooling time is presented graphically and. It mainly depends on wire feed rate welding speed arc voltage etc. Main and interaction effects of the process variables on bead geometry and shape.

Weld bead geometry and shape relationship PENETRATION Penetration is the distance that the fusion zone extends below the original surface of the parts being welded. As compared with all other welding processes SMAW. This is an indication of bead geometry.

Mathematical models to predict the weld bead geometry and shape relationships for the SAW of microalloyed steel. The purpose was to predict and control the weld bead geometry and shape relationship in submerged arc welding of pipes. Then the adequacy and significance.

S 25001 w mhr where I w is the welding current in amperes. They can be used in two ways.

Prediction And Optimization Of Weld Bead Geometry In Gas Metal Arc Welding Process Using Rsm And Fmincon Semantic Scholar

Prediction And Optimization Of Weld Bead Geometry In Gas Metal Arc Welding Process Using Rsm And Fmincon Semantic Scholar

Sensors Full Text Real Time Measurement Of Width And Height Of Weld Beads In Gmaw Processes

Sensors Full Text Real Time Measurement Of Width And Height Of Weld Beads In Gmaw Processes

Details Of Weld Groove Geometry And Bead Stacking Pattern For 130 Mm Scientific Diagram

Details Of Weld Groove Geometry And Bead Stacking Pattern For 130 Mm Scientific Diagram

Diagram For Measurement Of Bead Geometry Scientific Diagram

Diagram For Measurement Of Bead Geometry Scientific Diagram

Weld Bead Geometry Characteristics Along With Haz Width Deposition Table

Weld Bead Geometry Characteristics Along With Haz Width Deposition Table

The Solidified Reinforced Weld Bead Geometry During A Horizontal Scientific Diagram

The Solidified Reinforced Weld Bead Geometry During A Horizontal Scientific Diagram

Wire And Sheet Gauge Conversion To Inches And Millimeters Chart Jewelrymonk Together We Can Make The Best Jewelry Of Your Life Gauges Chart Wire

Wire And Sheet Gauge Conversion To Inches And Millimeters Chart Jewelrymonk Together We Can Make The Best Jewelry Of Your Life Gauges Chart Wire

Processes Full Text Bead Geometry Prediction Model For 9 Nickel Laser Weldment Part 1 Global Regression Model Vs Modified Regression Model

Processes Full Text Bead Geometry Prediction Model For 9 Nickel Laser Weldment Part 1 Global Regression Model Vs Modified Regression Model

Photographs Of The Bead Profile In Cross Section For The 32 Samples And Scientific Diagram

Photographs Of The Bead Profile In Cross Section For The 32 Samples And Scientific Diagram

Effects Of Welding Current And Arc Voltage On Fcaw Weld Bead Geometry

Effects Of Welding Current And Arc Voltage On Fcaw Weld Bead Geometry

Geometry Maps Following A Set Of Directions Students Designed Maps To Include Parallel Lines Perpendicular Lines Obtuse A Math Geometry Math Homeschool Math

Geometry Maps Following A Set Of Directions Students Designed Maps To Include Parallel Lines Perpendicular Lines Obtuse A Math Geometry Math Homeschool Math

Native American Indian Chief Headdress Welded Metal Art Sculpture Metal Art Sculpture Metal Art Welded Metal Art

Native American Indian Chief Headdress Welded Metal Art Sculpture Metal Art Sculpture Metal Art Welded Metal Art

A Schematic Diagram Of Weld Bead Geometry Scientific Diagram

A Schematic Diagram Of Weld Bead Geometry Scientific Diagram

Schematic Sketch Of A Tig Weld Bead Geometry Scientific Diagram

Metals Full Text Effect Of Weld Bead Shape On The Fatigue Behavior Of Gmaw Lap Fillet Joint In Ga 590 Mpa Steel Sheets

Metals Full Text Effect Of Weld Bead Shape On The Fatigue Behavior Of Gmaw Lap Fillet Joint In Ga 590 Mpa Steel Sheets

Materials Full Text Prediction Of Bead Geometry With Changing Welding Speed Using Artificial Neural Network

Materials Full Text Prediction Of Bead Geometry With Changing Welding Speed Using Artificial Neural Network

Basic Geometrical Concepts Coplanar Points Coplanar Lines Concurrent Lines And Space Geometry Kwiznet Math Science En Line Math Study Tips College Math

Basic Geometrical Concepts Coplanar Points Coplanar Lines Concurrent Lines And Space Geometry Kwiznet Math Science En Line Math Study Tips College Math

Hypercube Out Of Magnets Magnetic Games Magnetic Games Fun Magnets Magnets

Hypercube Out Of Magnets Magnetic Games Magnetic Games Fun Magnets Magnets

Geometry Of Prepared Grooves For Welding A I Groove Beveling With 5 Scientific Diagram

Geometry Of Prepared Grooves For Welding A I Groove Beveling With 5 Scientific Diagram

Processes Full Text Bead Geometry Prediction Model For 9 Nickel Laser Weldment Part 1 Global Regression Model Vs Modified Regression Model

Processes Full Text Bead Geometry Prediction Model For 9 Nickel Laser Weldment Part 1 Global Regression Model Vs Modified Regression Model

Mathematical Modeling And Optimization Of Weld Bead Geometry In Cladding By Flux Cored Arc Welding Semantic Scholar

Mathematical Modeling And Optimization Of Weld Bead Geometry In Cladding By Flux Cored Arc Welding Semantic Scholar

Diagram For Measurement Of Bead Geometry Scientific Diagram

Diagram For Measurement Of Bead Geometry Scientific Diagram

A Schematic Diagram Of Weld Bead Geometry Scientific Diagram

A Schematic Diagram Of Weld Bead Geometry Scientific Diagram

ctge1mma264myg37nhflylwudqwabyiswyfkdnl5nkfqilynmah